Blog

The Positive Effects of the Multiples Preview Window

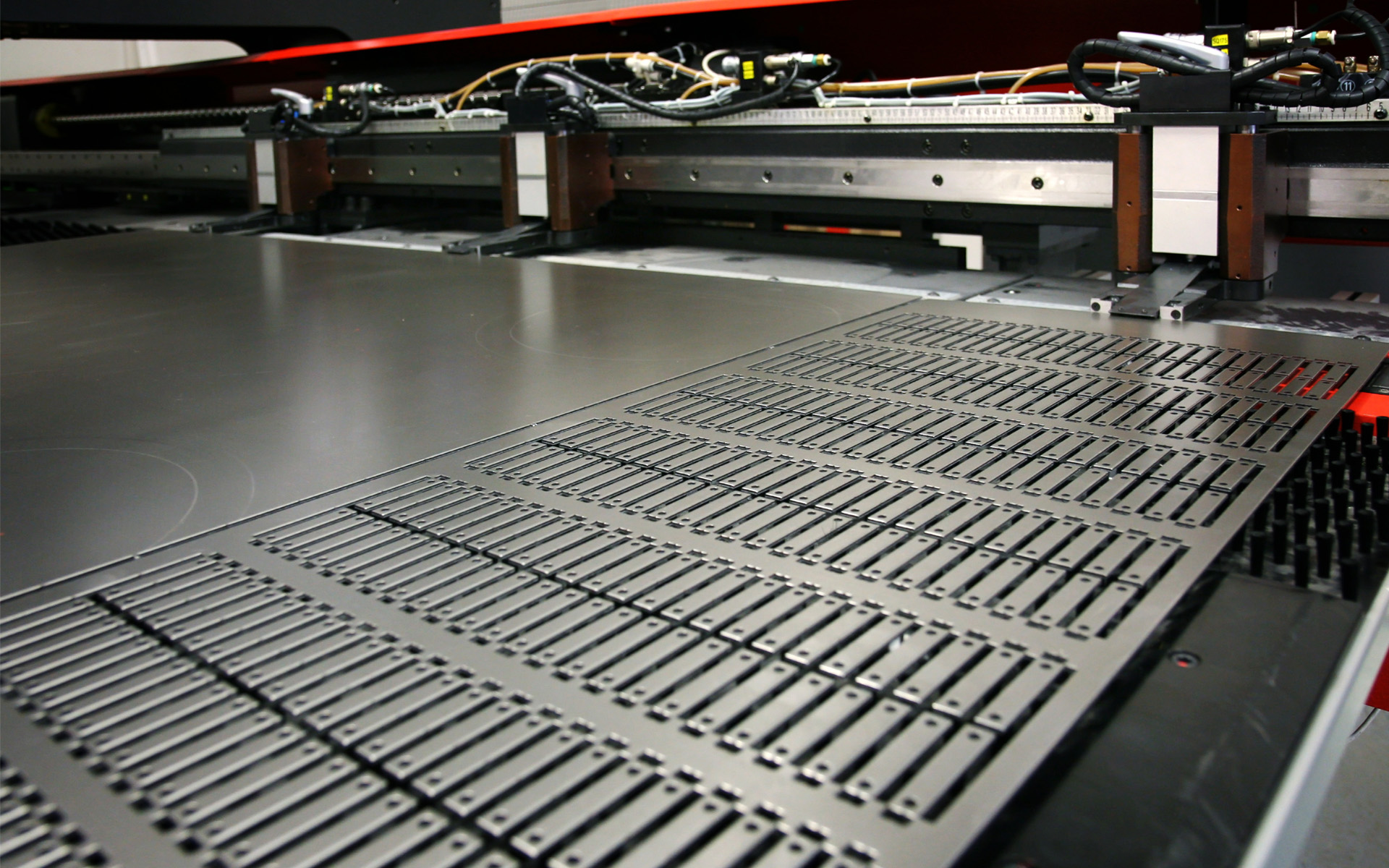

Merry Mechanization's SMP sheet metal fabrication software lets programmers optimize sheet metal use by making it easy to adjust all the factors involved in placing parts on a sheet. The software has automated features that can adjust sheet size or the number of parts fitted while at the same time giving the programmer full control to make changes. Trims and borders can be adjusted for clamp placement and part placement in grids while part spacing can be changed easily and the results seen instantly. The SMP software can reduce waste and improve productivity with just the right combination of programmer control and automatic features. The result is that borders, spacing, and part placement perfectly correspond to operational requirements and the parts are produced rapidly without problems.

Sheet Size

In the initial run of the program, the sheet size is either specified or it can be sized according to the number of parts placed on it. Certain sheets may be in stock so the programmer can change the size of the sheet to match what is available. The program calculates the new parts placement and displays the changes. The programmer can now make additional modifications to optimize parts placement.

The trims and borders can be easily adjusted lower to allow more parts on the sheet which will increase the need for repositioning the clamps or increase the trims and borders which will prevent clamps from needing to be moved but may have less parts fit on the sheet. In either instance, the programmer can widen or shrink the border, change sheet size or rearrange the part rows or columns. In each case, the intuitive graphical interface of the Multiples Preview Window allows the programmer to easily indicate the changes required and to see immediately what the results are. If the new arrangement doesn't work, they can go back and try a different combination of changes.

If the sheet size is reduced, the required number of parts may no longer fit but a reduction in the borders may make room for more parts. The programmer can easily try out different arrangements and combinations of border and sheet sizes to find the best solution. All sheet size changes and border adjustments are clearly and accurately displayed by the SMP program.The result is that borders, spacing, and part placement perfectly correspond to operational requirements and the parts are produced rapidly without problems.

Parts Placement

Often the sheet sizes are fixed but the programmer wants to place as many parts as possible on one sheet to minimize waste and reduce scrap. The number of columns and rows of parts can be adjusted and the borders on different sides of the sheet can be changed independently.

Different parts may need more or less space. A combination of manual actions and automated calculations let the programmer quickly arrive at the best possible solution.

Parts Spacing

In addition to sheet size and the number of parts to be fabricated, parts spacing can be important for high quality output. When placed manually, parts may have developed a slight overlap or they may be too close for the tools to be used or for web stability. Programmers can have the program display areas of concern in detail and can make changes to avoid problems during punching and cutting. Programmers can identify where problems might occur and implement fixes that ensure the parts fabrication process can run smoothly.

If part spacing looks too tight in the overview, programmers can zoom in to see detailed views at critical points. Part spacing can be adjusted manually or automatically, overlaps can be eliminated and tight spacing adjusted. The command for part spacing operates at the point where parts have the smallest gap and the single command can reposition all the parts in a new grid with new spacing.

The SMP program also shows tooling for the part edges that are closest together. Sometimes the spacing is not enough to allow the selected tool to operate properly on the two adjacent parts. In that case another tool option can be selected or the parts can be moved to allow for greater spacing. The programmer can try different strategies to make sure part fabrication proceeds without problems while at the same time maintaining the greatest number of parts on the sheet.A combination of manual actions and automated calculations let the programmer quickly arrive at the best possible solution.

When parts are too close together, web stability can suffer and may cause problems during fabrication. Web stability depends on sheet thickness and part spacing, so the programmer can make adjustments and immediately see the results. The SMP software allows the programmer to take all these factors into consideration, helps them see the results of changes they make, and facilitates the implementation of the best solution.

Overall Results Summary

The Multiples Preview Window feature of the SMP application presents the programmer with a proposed layout and lets him make appropriate changes to maximize sheet metal use and avoid production problems. Specific commands include the following,

- Adjust the width of borders

- Add parts, either in rows, columns or independently

- Change sheet metal sheet size

- Adjust number of parts to fit sheet

- Adjust sheet size to fit specified number of parts

- Change part spacing

- Zoom to display spacing, tooling and part details

Merry Mechanization developed the SMP sheet metal fabrication program to help make part production efficient and reduce time spent on standard tasks. The Multiples Preview Window feature lets experienced programmers make improvements to automatically or manually generated borders and parts placement while reducing programming time and sheet metal waste.