PRO Features

Seamless CAD/CAM environment that marries design and manufacturing to increase throughput.

PRO Features Our PRO Features increase productivity and output.

AutoNest®

AutoNest® is a schedule-based, automatic, rectangular nesting routine designed to maximize material usage and reduce machine setup time. It is a cost-effective way for fabricators to meet JIT manufacturing requirements.

NestMaster®

NestMaster® true-shape nesting is designed to nest sheet metal parts, maximize material utilization, increase productivity, and decrease turnaround time. The program reads a list of programmed parts, analyzes the real geometry of each part, and nests them together on blank material stock.

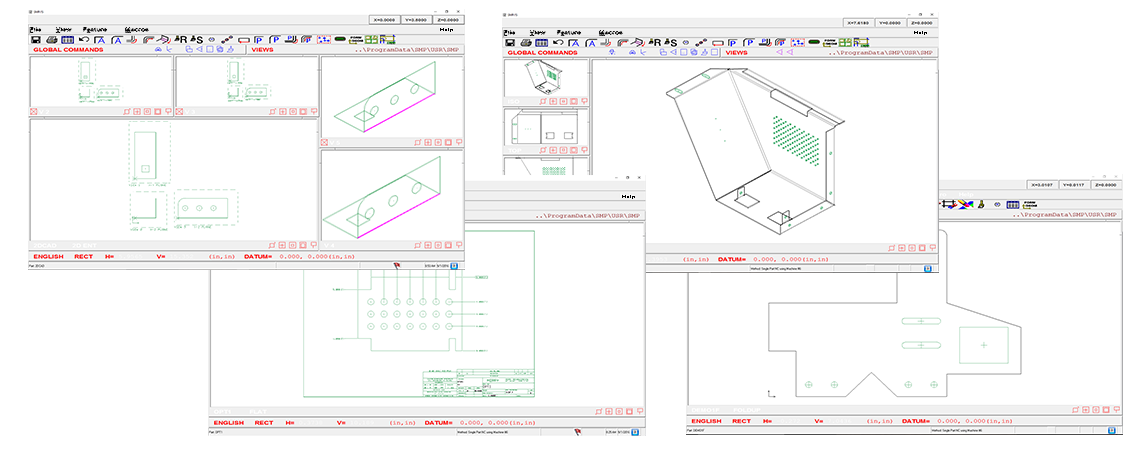

Total Nesting Automation

TNA is designed to process your parts from start to finish without user intervention. Just add a batch of CAD files or existing SMP parts to the CAD File List and specify how you want the parts to be programmed and nested.

NC Readback

NC Readback recreates part designs from existing, machine-specific NC and tooling programs. NCRB converts nests or multiples of parts into a DXF files. You can convert a single NC code file manually or batches of files automatically.

Font Outline Import

Mark, etch, scribe, cut, or punch text on any SMP part. Font Outline Import works with all regular style fonts installed on your computer.

DWG Translator

Automatically converts DWG files during import to DXF format for seamless importing directly into SMP/IS.

SolidWorks® Translator

Opens SMP from within SolidWorks using a Plug-in, brings your part in as a flat pattern ready to define tooling or cutting in SMP/IS.

AutoMate Express w/ Multiple Machines

AutoMate Express automatically imports batches of CAD files and processes them to writing NC code. You can run AutoMate Express unattended or select stopping points along the way to spot check.