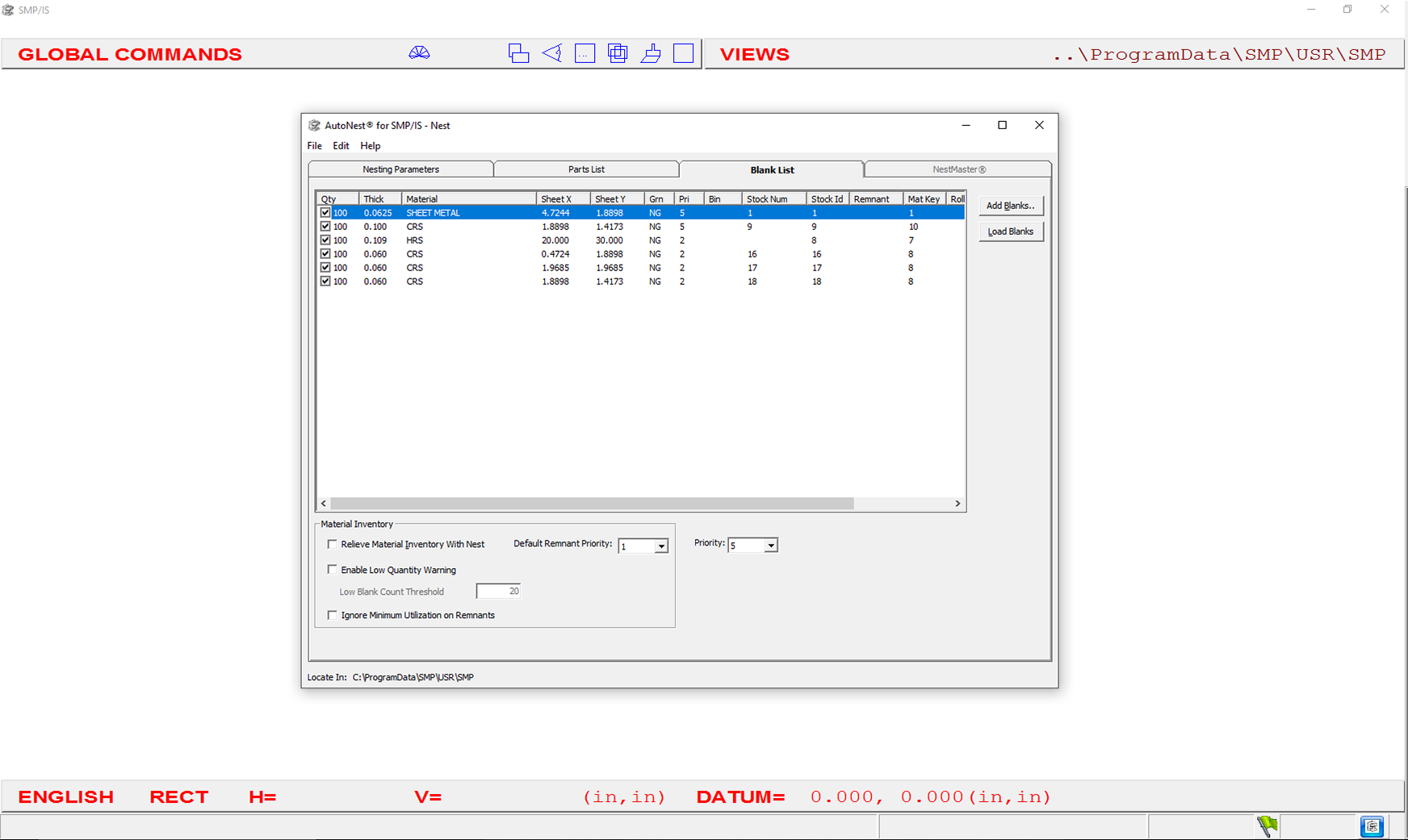

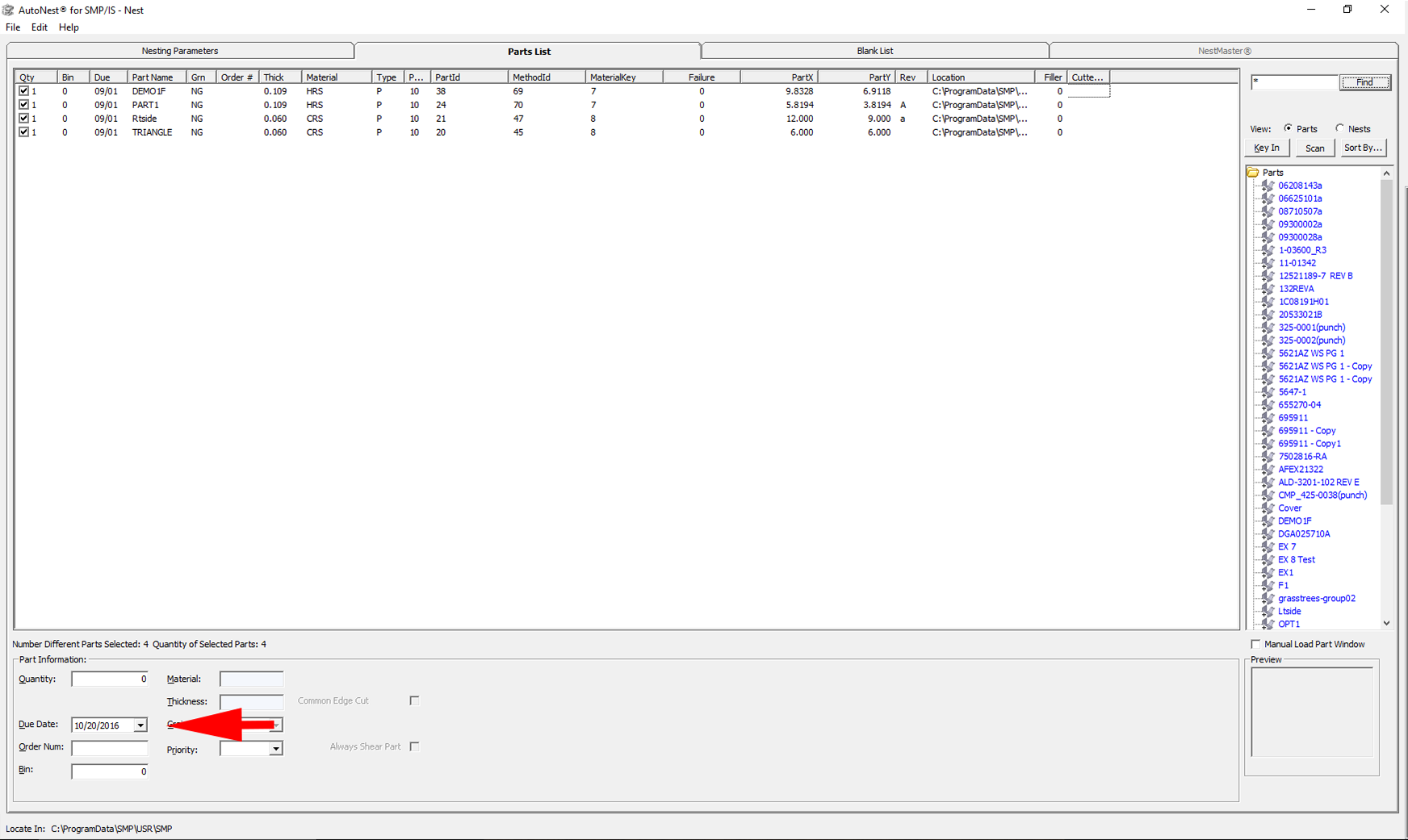

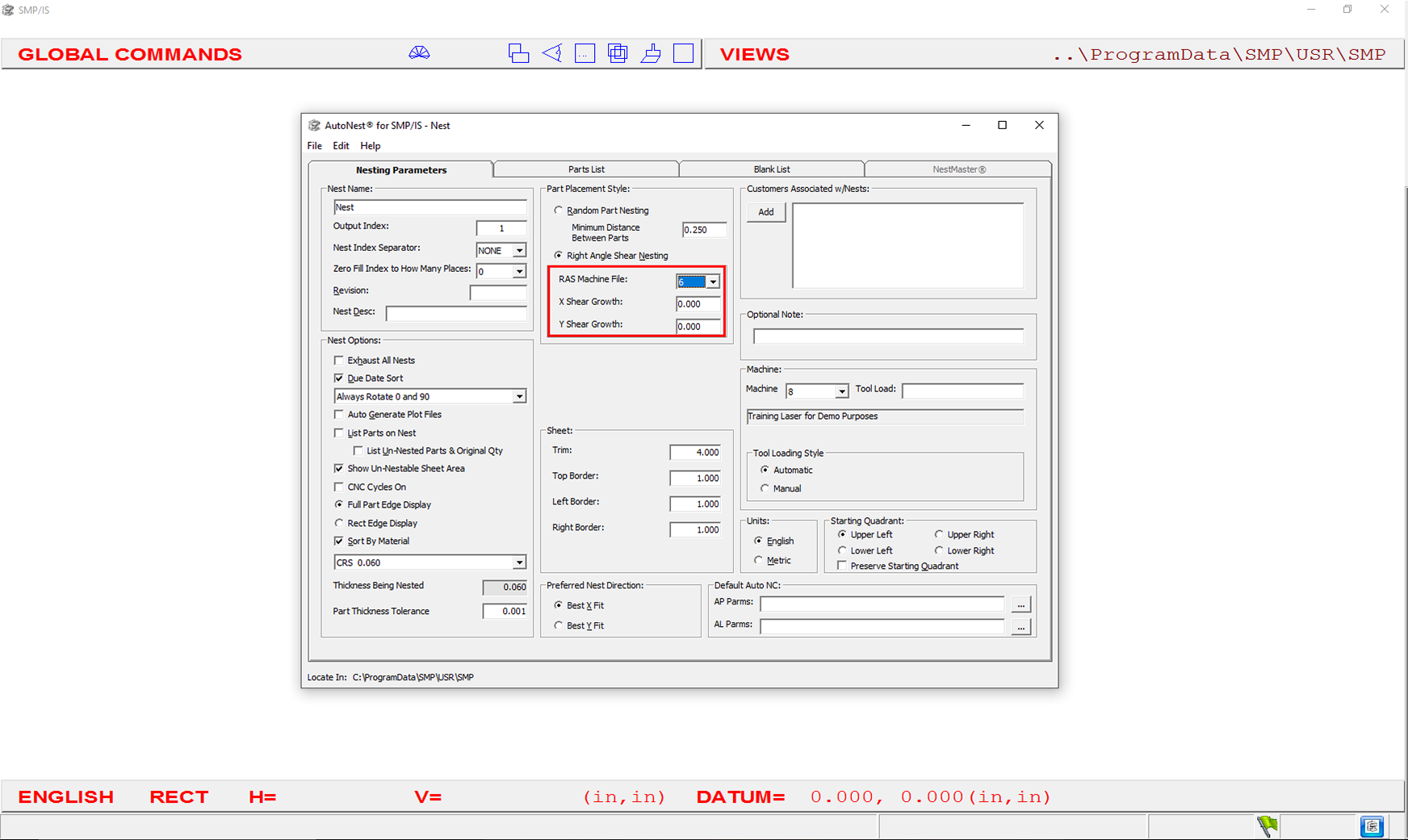

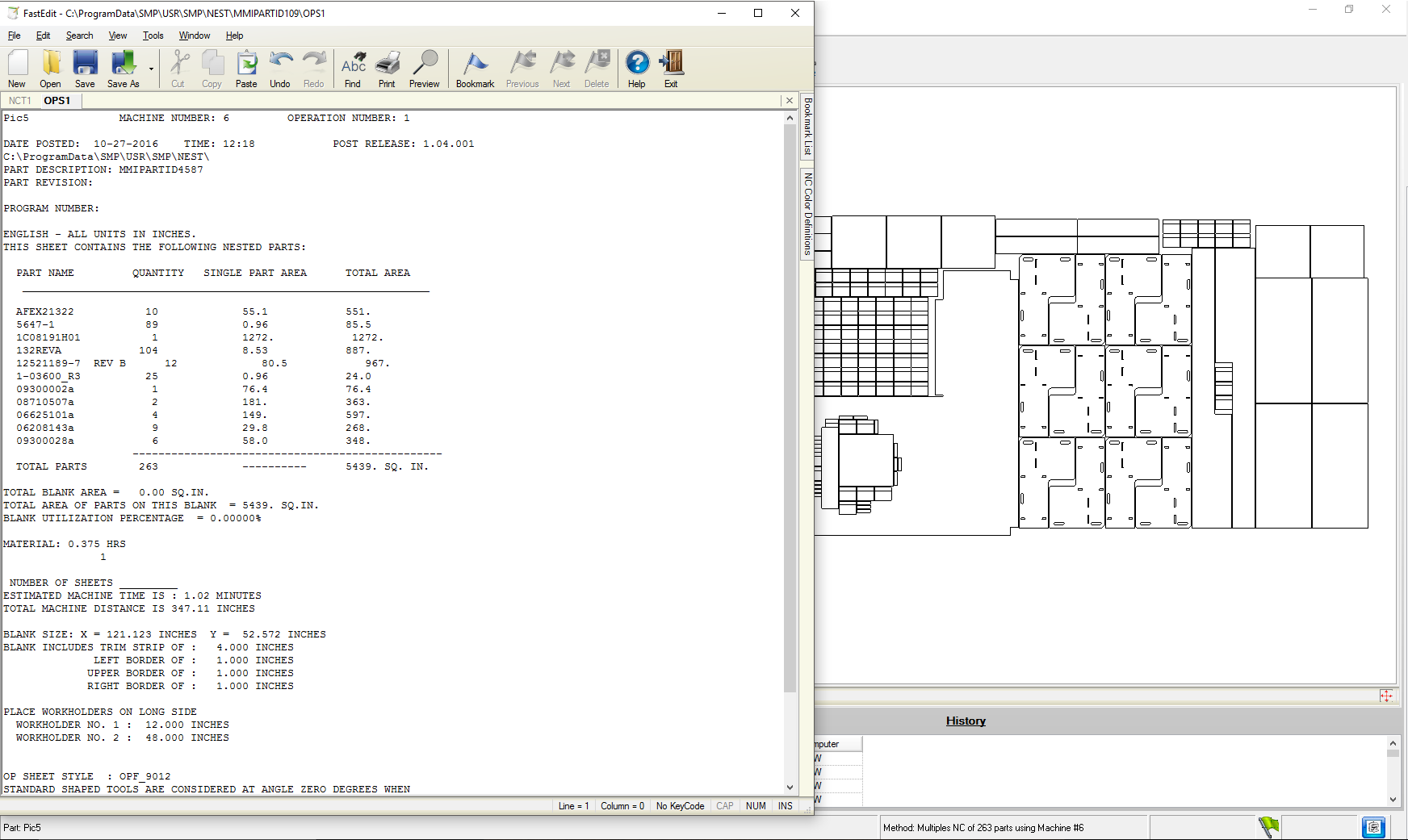

AutoNest

Automatically Nest Parts

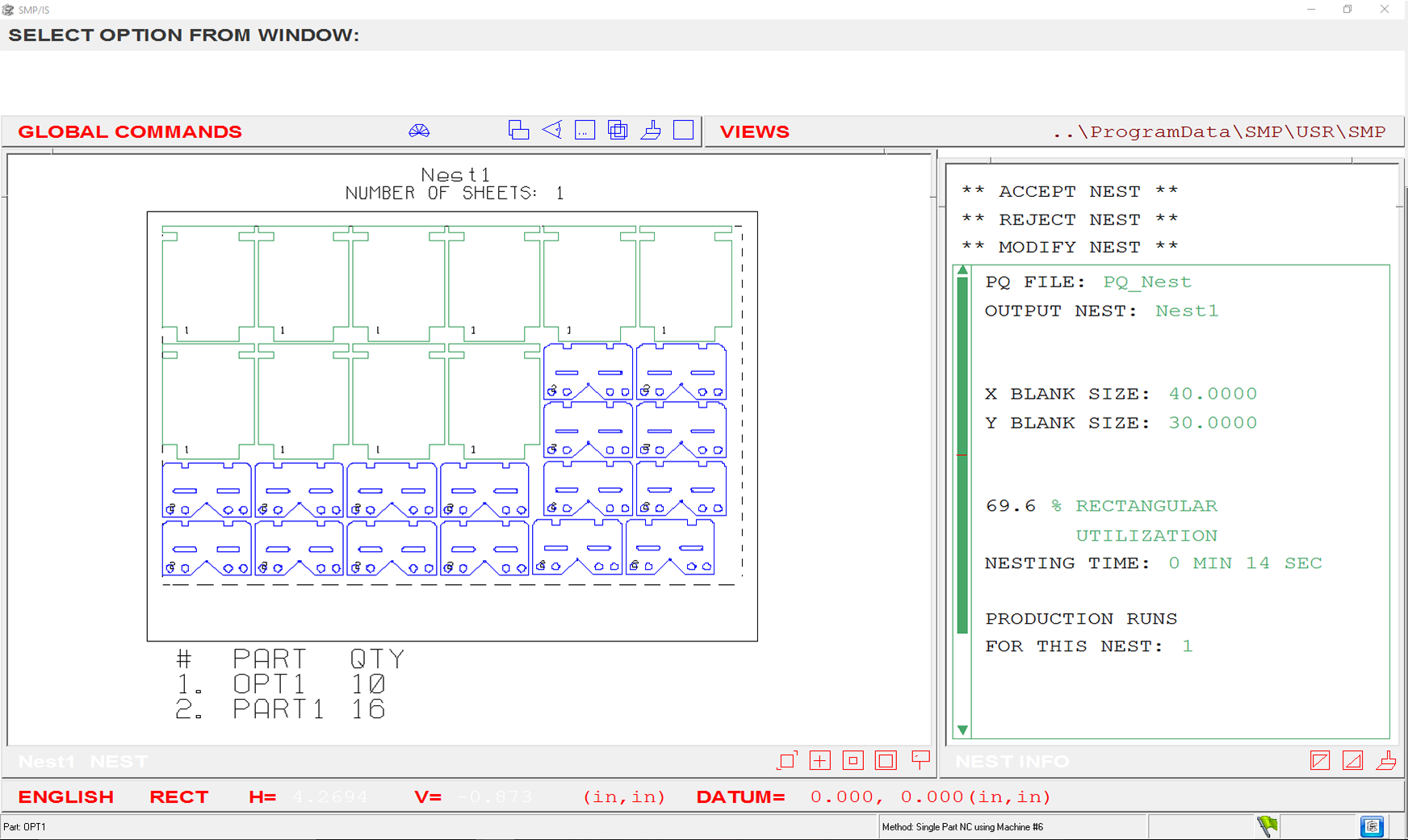

From your list of parts and sub-nests AutoNest® will provide the “best” nest based on production requirements and material usage, optimize the tool path, check for interference and perform needed repositioning.

Flexible Programming

Alternately, AutoNest can be used to program a RAS for blanking by loading the input list with rectangle sizes and quantities.