Nesting Software

Save Time and Material without Sacrificing Control

Nesting Features Save Time and Material without Sacrificing Control

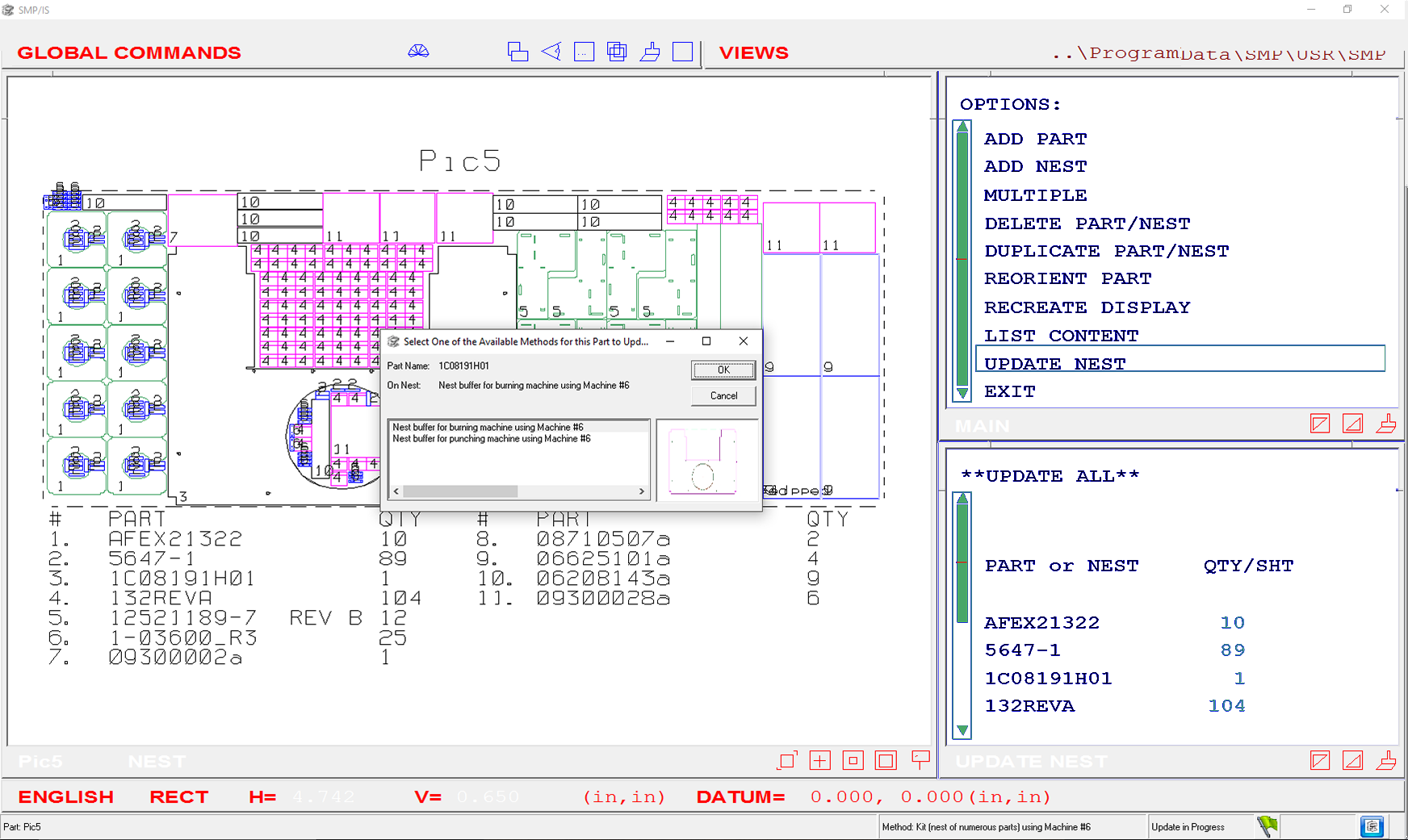

Interactive Nesting

The SMP/IS Interactive Nesting routine gives you total control over part placement. It allows you to interactively create nests of parts and then treat that nest as a single entity within the program. Any number of parts may be placed on an individual blank. The nest may contain any quantity of one specific part, many different parts, or all of the parts required for an assembly.

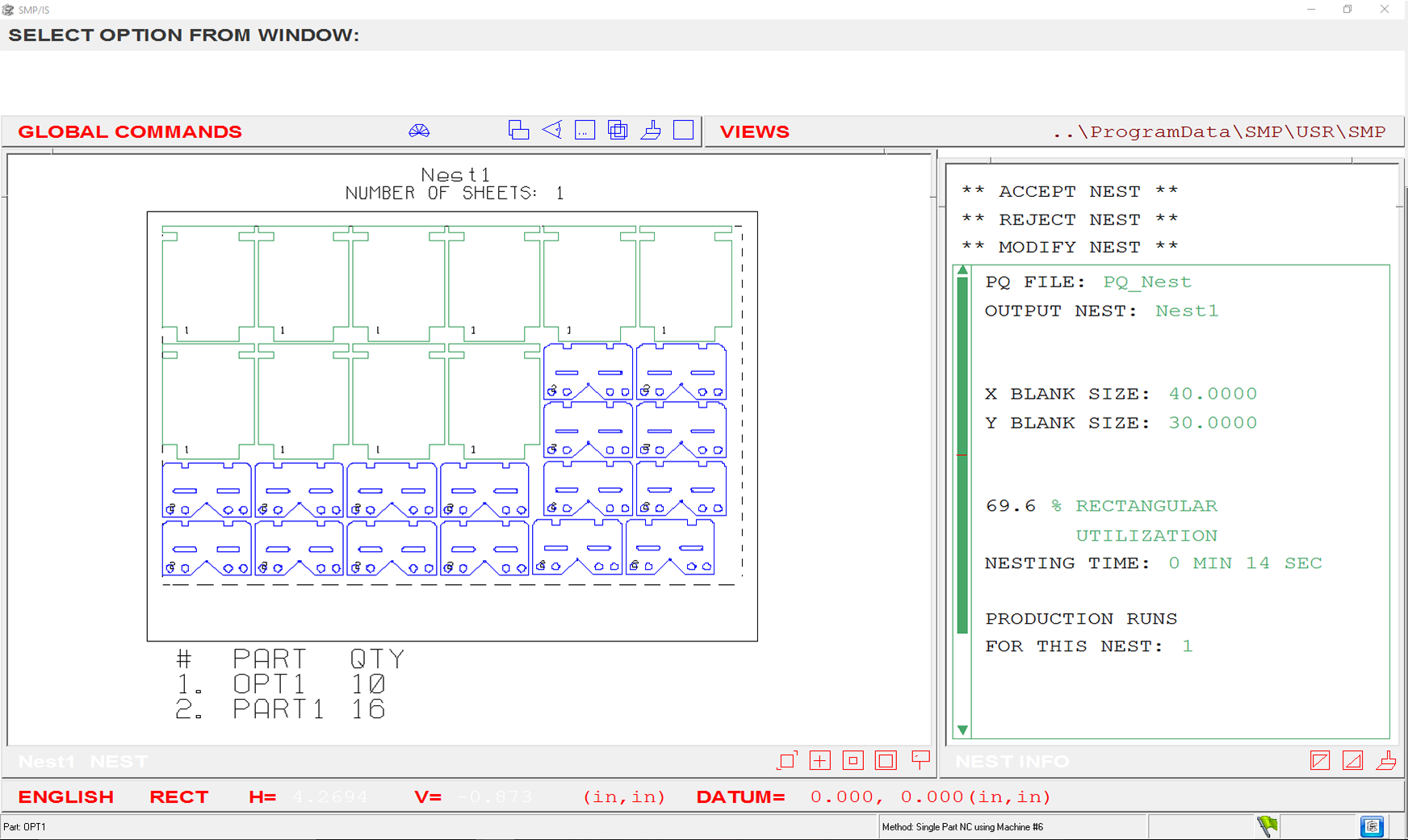

Learn MoreAutoNest®

AutoNest® is a schedule-based, automatic, rectangular nesting routine designed to maximize material usage and reduce machine setup time. It is a cost-effective way for fabricators to meet JIT manufacturing requirements.

*Included in PRO Subscription

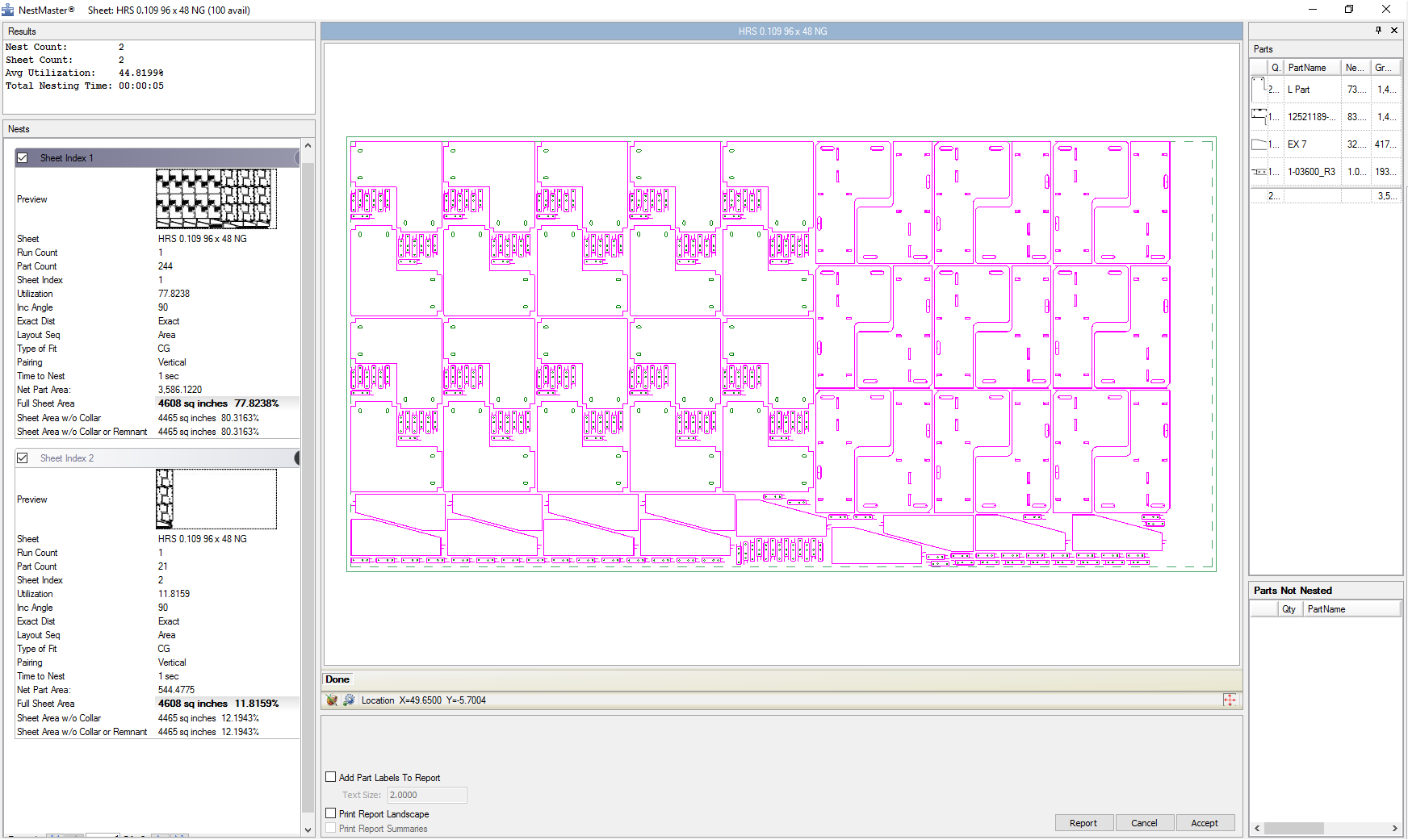

NestMaster®

NestMaster® true-shape nesting is designed to nest sheet metal parts, maximize material utilization, increase productivity, and decrease turnaround time. The program reads a list of programmed parts, analyzes the real geometry of each part, and nests them together on blank material stock. NestMaster® can read in a comma-delimited ASCII file to generate a list of parts to nest. This file can be created by an MRP/ERP system or any other software. NestMaster® has been specifically designed to run your punch machines, cutting machines, or combination machines.

*Included in PRO Subscription

Total Nesting Automation™

Total Nesting Automation is designed to process your parts from start to finish without user intervention. Just add a batch of CAD files or existing SMP parts to the CAD File List and specify how you want the parts to be programmed and nested. Then you just click a button and walk away!

*Included in PRO Subscription

Comparison ChartSee all of our favorite nesting plans side by side

|

AutoNest® Automatic Rectangular Nesting Software. Learn more | NestMaster® Automatic True Shape Nesting Software. Learn more | Total Nesting Automation™ CAD to Nested Optimized Code Unattended. Learn more |

| Supports: | |||

| Punch Machines | |||

| Laser Machines | |||

| Waterjet Machines | |||

| Plasma Machines | |||

| Oxyfuel Machines | |||

| Combination Machines | |||

| Right Angle Shear Machines | |||

| Part PQ Features: | |||

| MRP/ERP Import | |||

| Nest Sub-Nests | |||

| Part Priorities | |||

| Part Grain Restrictions | |||

| Due Date Sort | |||

| Filler Parts | |||

| Disassemble Sub-Nests | |||

| Barcode Scanning | |||

| CAD File Import | |||

| Processing Options: | |||

| Auto Create Plot Files | |||

| Create Cutoff Cycles | |||

| Automatically Remove Duplicates | |||

| Automatically Add Pattern Locks | |||

| Automatically Add Subroutines | |||

| Automatically Resequence Tooling | |||

| Automatic Optimization | |||

| Automatic Repositioning | |||

| Auto NC | |||

| Automatically Write NC Code | |||

| Material Management: | |||

| Material Priorities | |||

| Material Grain Restrictions | |||

| Set Trims and Borders | |||

| Nest on Remnants | |||

| Rolled Sheet Cutoff | |||

| Nesting Options: | |||

| Rectangular Nesting | |||

| Common Edge | |||

| Preferred Nesting Direction | |||

| Starting Quadrant | |||

| True Shape Nesting | |||

| Parts Inside of Parts | |||

| Advanced Material Sheet Utilization | |||

| Recycle Remnants | |||

| Sheet Acceptance Type | |||

| Printable Nest Report | |||

| Web Breakup | |||

| Oversized Part Options | |||

| Shear Top | |||

| Always Shear Part | |||

| Part Sheared to Size | |||

| Part Control: | |||

| Part Spacing Control | |||

| Part Sort Sequence | |||

| Part Pairing | |||

| Part Angle Control | |||

| Part Mirroring | |||

| Type of Part Fit | |||

| Advanced Grid Fit | |||

| Large Arc Radius Override | |||